PET is one of the high performance polymer that can be used in multiple engineering applciations. It requires a carefully formulated compound to get most out of PET. Spearepet has developed a portfolio of PET based engineering compounds which can replace expensive engineering resins in several applciations. The portfolio includes unfilled, supertough, glass filled, glassfilled FR and mineral filled grades. PET combines performance with excellent flow characteristics enabling thin wall applications in electrical industry. The glass filled grades have superior modulus and strength characteristics that enable replacement of metals with plastic

| Unfilled PET | Glass Filled PET | Mineral Filled PET | PET/PBT Blends | PET Glass Filled FR |

|---|---|---|---|---|

| 0.8 - 0.9 IV | 15% GF PET | 15% Mineral PET | PET rich GF | FR PET 30% GF |

| Medium Impact | 20% GF PET | 25% Mineral PET | PBT rich GF | FR PET 33% GF |

| High Impact | 30% GF PET | 15 GF+10 Mineral PET | Impact Modified | FR PET 40% GF |

Today Electrical & Electronics (E & E) industry demands smaller & thinner components, long life, cost

effectiveness combined with more stringent regulations.

Spearepet developed modified PET grades that support thin wall molding with superior performance

properties like flame retardancy and electrical properties.

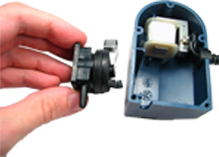

The applications include solar junction boxes, electrical connectors, transformer bobbins and enclosures.

One of the continuous opportunity in automotive is metal replacement for weight reduction. The opportunity is extended to thinner designs in existing plastic parts.

When it comes thin wall combined with high mechanical properties, glass filled PET is one of the excellent choice for designers.

Spearepet has developed thin wall mold-able, impact modified glass filled PET compounds to meet the rising demands of auto industry.

Modified PET can be used in brake booster valve bodies, mirror brackets and lighting frames etc in automotive.

Engineering Thermoplastics are widely used in several industrial applications for its strength and ease of manufacturing.

Modified PET is certainly a choice for metal replacement or high temperature resistance needs.

Spearepet has capability to tune the product to the custom needs of customers and also capable of supporting entire application development process.

The wide portfolio of Spearepet grades provide an economical option to customer to consider developments based on PET.

Consumer segment is always challenging in meeting the dynamic design requirements combined with pressure on cost effectiveness.

For applications like appliance housing, invertor housing or housing for consumer durables, modified PET can be an economical choice combined with performance attributes.

Contact Spearepet in design stage to explore most economical and sustainable resin solution.